2025-03-04

The morning sunlight spilled into the workshop. Today is another day full of challenges and rewards - the mechanical assembly of the weighing body of the Checkweigher scale. This seemingly ordinary task is actually crucial in every aspect, as it determines whether the checkweigher scale can operate accurately and stably.

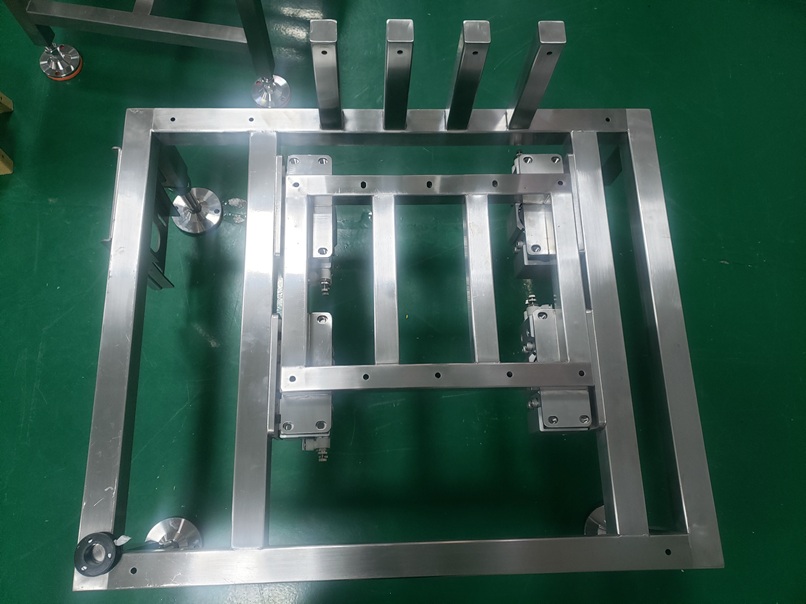

Entering the workshop, the first thing that catches my eye is the workbench piled high with parts. Today's task is to assemble a high-precision checkweigher scale, starting from the most basic framework construction. I carefully picked up the main frame of the weighing body. This is the supporting structure of the entire weighing body, made of sturdy material and finely processed to ensure that the dimensional accuracy reaches the millimeter level. I placed the frame firmly on the workbench and then began to install the supporting feet at the bottom. These supporting feet not only have to bear the weight of the weighing body but also ensure the stability of the weighing body in various working environments. Therefore, during the installation process, we must strictly follow the design requirements to ensure that the height of each supporting foot is consistent and the horizontal error is controlled within a very small range. I used a professional level gauge to measure and adjust carefully. Every slight adjustment may affect the final weighing accuracy.

After the framework was set up, we moved on to the installation of the core component - the weighing sensor. The weighing sensor is like the "heart" of the checkweigher scale, and its performance directly determines the accuracy and reliability of the scale. I carefully took out the sensor from the packaging box. This precise component seemed to carry the key to the entire project in my hands. According to the installation drawing, I accurately installed the sensor in the designated position of the frame and then carried out the wiring connection. The wiring connection requires extra care. The interface of each wire must be ensured to be firm and not loose, otherwise, it may lead to unstable signal transmission and affect the accuracy of the weighing data. During the connection process, I checked each interface repeatedly to ensure everything was foolproof.

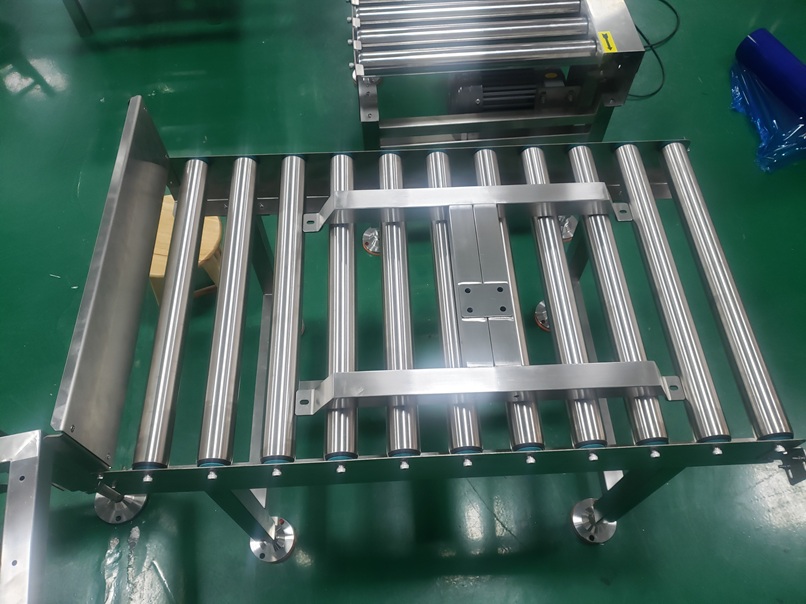

After installing the sensor, the next step was the installation of the conveyor belt. The conveyor belt is an important part of the checkweigher scale for material transportation, and the flatness of its installation and the control of tension are very crucial. I first installed the driving device of the conveyor belt at one end of the frame, then passed the conveyor belt around each roller, adjusted the position of the conveyor belt to make it perfectly match with other parts of the weighing body. When adjusting the tension of the conveyor belt, I used a professional tensiometer to ensure that the tension was within the appropriate range. If the tension is too high, it will accelerate the wear of the conveyor belt and affect its service life; if the tension is too low, the conveyor belt may slip and fail to transport materials properly. After some careful adjustments, the conveyor belt was finally installed. I started the motor for a trial run, and seeing the conveyor belt running smoothly, a sense of accomplishment welled up in my heart.

During the assembly process, it was inevitable to encounter some problems. For example, when installing some parts, I found that there was a slight deviation in the fit between the parts, which might be caused by errors during the processing. In such a situation, I first carefully checked the drawing to confirm whether the installation steps were correct. Then, I used measuring tools such as a caliper to accurately measure the dimensions of the parts and find out the specific position and magnitude of the deviation. For some slight deviations, I tried to use fitter tools for fine-tuning, such as a file, sandpaper, etc., and properly polished the surface of the parts to enable them to be installed smoothly. After some efforts, I finally successfully solved the problem of part fitting and ensured the smooth progress of the assembly work.

As time went by, each component of the checkweigher scale was gradually assembled. Before the final overall machine debugging, I carried out a comprehensive inspection of each component to ensure that all the screws were tightened, the wiring connections were firm, and the conveyor belt was running smoothly. Once everything was ready, I started the control system of the checkweigher scale and began the weighing test. I placed the standard weights on the weighing platform one by one and observed the weight data displayed on the screen. By comparing with the actual weight of the weights, I found that the accuracy of the scale basically met the design requirements, but there were still some slight deviations. So, I entered the control system again and carried out fine calibration of the zero point and range of the scale. After several adjustments and tests, the weighing accuracy of the checkweigher scale finally reached the desired state, and each weighing data was accurately displayed on the screen.

Looking at the assembled and successfully debugged checkweigher scale, my heart was filled with joy and satisfaction. The hard work of this day was rewarded in the best way at this moment. Although I encountered many difficulties during the process, through continuous efforts and exploration, I finally successfully completed the task. In this process, I not only improved my technical ability but also deeply realized the importance of teamwork and a rigorous work attitude. Tightening each screw and installing each component embodied the painstaking efforts and sweat of everyone.

The afterglow of the setting sun shone in the workshop, marking the end of this busy and fulfilling day. I look forward to facing new challenges tomorrow and continuing to create more value in the work of checkweigher scale assembly.

Contact: Mr.Bai

Phone: +86 19905190705

Tel: +86 19905190705

Email: 623605936@qq.com

Add: No. 58, Leshan West Road, Xinbei District, Changzhou City, Jiangsu Province